Mastering the Screw Bolt Extractor: A Comprehensive Guide

Stubborn screws and bolts can turn a simple DIY project into a frustrating ordeal. Whether you’re a seasoned mechanic or a weekend warrior, encountering a stripped, broken, or rusted fastener is almost inevitable. That’s where a screw bolt extractor becomes an indispensable tool. This comprehensive guide will delve into the world of screw bolt extractors, covering everything from understanding their types and uses to mastering the techniques for effective extraction. We’ll also explore common pitfalls and provide expert tips to ensure you conquer even the most challenging fastener removal tasks.

Understanding Screw Bolt Extractors

A screw bolt extractor is a specialized tool designed to remove damaged screws, bolts, studs, and other fasteners that are otherwise impossible to remove using conventional methods. These tools work by gripping the damaged fastener and providing a means to apply torque, allowing you to unscrew it. The principle behind their effectiveness lies in their reverse-threaded or tapered design, which digs into the damaged fastener as you attempt to turn it in the loosening direction.

Types of Screw Bolt Extractors

- Spiral Flute Extractors: These extractors feature a spiral flute design that bites into the damaged fastener as you turn it counterclockwise. They are best suited for removing screws and bolts with moderately damaged heads.

- Straight Flute Extractors: Straight flute extractors have straight flutes that provide a more aggressive grip on the damaged fastener. They are ideal for removing severely damaged or broken screws and bolts.

- Easy Out Extractors: “Easy Out” is a common name for a type of tapered, hardened steel extractor that is hammered into a drilled hole in the damaged fastener. As you turn the extractor, it wedges itself further into the hole, providing a strong grip for removal.

- Nut Extractors: These extractors are specifically designed for removing damaged or rounded nuts. They feature a reverse spiral design that grips the nut tightly, allowing you to apply torque without slipping.

- Screw Extracting Pliers: These pliers have specially designed jaws that grip the head of a screw or bolt, even if it’s stripped or damaged. They are a versatile option for removing various types of fasteners.

How to Use a Screw Bolt Extractor: A Step-by-Step Guide

Using a screw bolt extractor effectively requires careful preparation and technique. Here’s a step-by-step guide to help you through the process:

- Preparation: Before you begin, gather the necessary tools and materials, including the appropriate screw bolt extractor, a drill, drill bits (including a center punch), penetrating oil, a hammer, and a wrench or socket set.

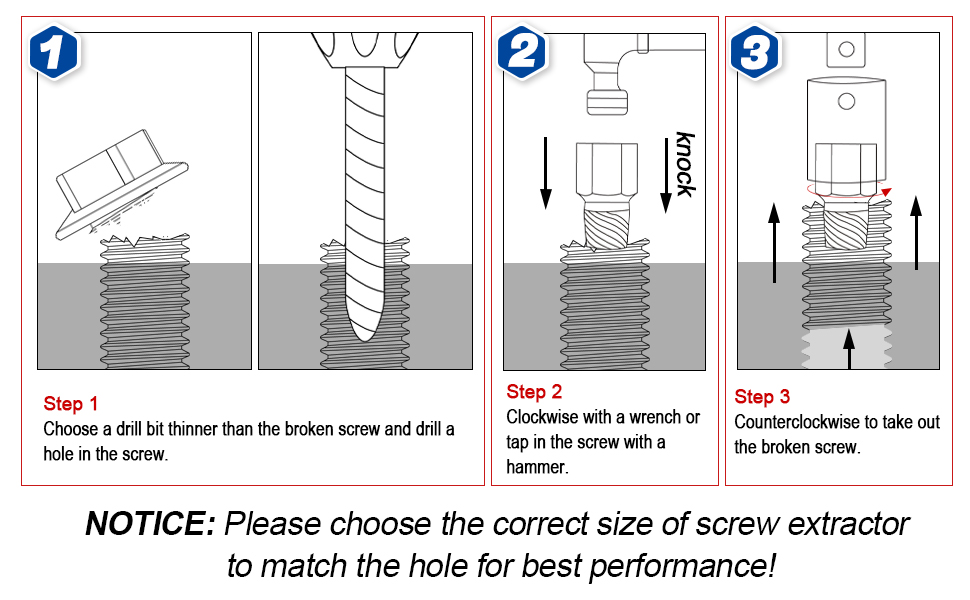

- Center Punch: Use a center punch to create a small indentation in the center of the damaged fastener. This will help guide the drill bit and prevent it from wandering.

- Drilling: Select a drill bit that is slightly smaller than the diameter of the screw bolt extractor you will be using. Drill a pilot hole into the center of the damaged fastener. The depth of the hole should be approximately half the length of the extractor.

- Inserting the Extractor: Insert the screw bolt extractor into the drilled hole. For tapered extractors like “Easy Outs,” gently tap the extractor into the hole with a hammer until it is firmly seated.

- Extraction: Using a wrench or socket set, slowly turn the screw bolt extractor counterclockwise. Apply steady pressure and avoid using excessive force, which could break the extractor or further damage the fastener.

- Penetrating Oil: If the fastener is particularly stubborn, apply penetrating oil around the area and allow it to soak for several minutes. This will help loosen the corrosion and make extraction easier.

- Repeat if Necessary: If the fastener does not budge, repeat steps 4-6, applying more penetrating oil and using a slightly larger screw bolt extractor if needed.

Tips for Effective Screw Bolt Extraction

While the basic process of using a screw bolt extractor is straightforward, mastering the technique requires attention to detail and a few helpful tips:

- Choose the Right Extractor: Select the appropriate type and size of screw bolt extractor for the specific fastener you are trying to remove. Using the wrong extractor can damage the fastener or the tool.

- Use Penetrating Oil: Penetrating oil is your best friend when dealing with stubborn fasteners. Apply it liberally and allow it to soak for several minutes before attempting extraction.

- Apply Steady Pressure: Avoid using excessive force when turning the screw bolt extractor. Steady, even pressure is more effective than brute force.

- Heat the Area: Applying heat to the surrounding area can help loosen corrosion and make extraction easier. Use a heat gun or torch, but be careful not to damage any nearby components.

- Tap the Fastener: Gently tapping the head of the damaged fastener with a hammer can help break the corrosion and loosen it.

- Consider Left-Handed Drill Bits: Using a left-handed drill bit can sometimes cause the fastener to unscrew itself during the drilling process.

- Clean the Threads: After removing the damaged fastener, clean the threads of the hole to ensure a proper fit for the replacement fastener.

Common Mistakes to Avoid

Even with the best tools and techniques, mistakes can happen. Here are some common pitfalls to avoid when using a screw bolt extractor:

- Using the Wrong Size Extractor: Using an extractor that is too small can strip the fastener, while using one that is too large can damage the threads.

- Applying Excessive Force: Using too much force can break the extractor or further damage the fastener.

- Drilling Too Deep: Drilling too deep can weaken the fastener and make it more difficult to extract.

- Not Using Penetrating Oil: Skipping the penetrating oil step can make extraction much more difficult, especially for corroded fasteners.

- Ignoring Safety Precautions: Always wear safety glasses and gloves when using power tools and handling potentially hazardous materials.

Advanced Techniques for Stubborn Fasteners

Sometimes, even the best techniques aren’t enough to remove a particularly stubborn fastener. In these cases, you may need to resort to more advanced methods:

- Welding a Nut: If the head of the fastener is broken off, you can weld a nut to the remaining stud. This provides a solid grip for applying torque.

- Using a Slide Hammer: A slide hammer can be used to apply a strong pulling force to the fastener, which can help break it free.

- Consulting a Professional: If you’ve exhausted all other options, it may be time to consult a professional mechanic or machinist. They have the tools and expertise to handle even the most challenging fastener removal tasks.

Choosing the Right Screw Bolt Extractor Kit

Investing in a high-quality screw bolt extractor kit is essential for any serious DIYer or professional mechanic. When choosing a kit, consider the following factors:

- Variety of Sizes: Look for a kit that includes a range of extractor sizes to accommodate different fastener sizes.

- Material Quality: Choose extractors made from high-quality steel for durability and longevity.

- Case and Organization: A well-organized case will help you keep track of your extractors and prevent them from getting lost.

- Reviews and Reputation: Read online reviews and research the reputation of the manufacturer before making a purchase.

Maintaining Your Screw Bolt Extractor Kit

To ensure your screw bolt extractor kit lasts for years to come, proper maintenance is essential:

- Clean After Use: Clean the extractors after each use to remove any debris or corrosion.

- Store Properly: Store the extractors in a dry, protected location to prevent rust and damage.

- Sharpen as Needed: If the extractors become dull, sharpen them using a file or grinding wheel.

- Replace Damaged Extractors: Replace any extractors that are damaged or broken to prevent injury and ensure effective extraction.

The Future of Screw Bolt Extraction Technology

As technology advances, we can expect to see even more innovative screw bolt extractor designs and techniques emerge. Some potential future developments include:

- Self-Adjusting Extractors: Extractors that automatically adjust to the size and shape of the damaged fastener.

- Wireless Extractors: Battery-powered extractors that provide greater portability and convenience.

- AI-Powered Extraction Systems: Systems that use artificial intelligence to analyze the damage to the fastener and recommend the optimal extraction technique.

Mastering the art of screw bolt extraction is a valuable skill that can save you time, money, and frustration. By understanding the different types of extractors, following the proper techniques, and avoiding common mistakes, you can conquer even the most challenging fastener removal tasks. Remember to always prioritize safety and consult a professional when necessary.

[See also: Removing Stripped Screws Like a Pro]

[See also: Best Penetrating Oils for Rusted Bolts]

[See also: Understanding Bolt Grades and Markings]